Industrial

Sim Lanka exports a variety of solutions to many industries including Doctor blades, Static Eliminators, Industrial Oil Purifications and some other equipment and machineries to enhance efficiency and functionality. Our solutions can transform businesses.

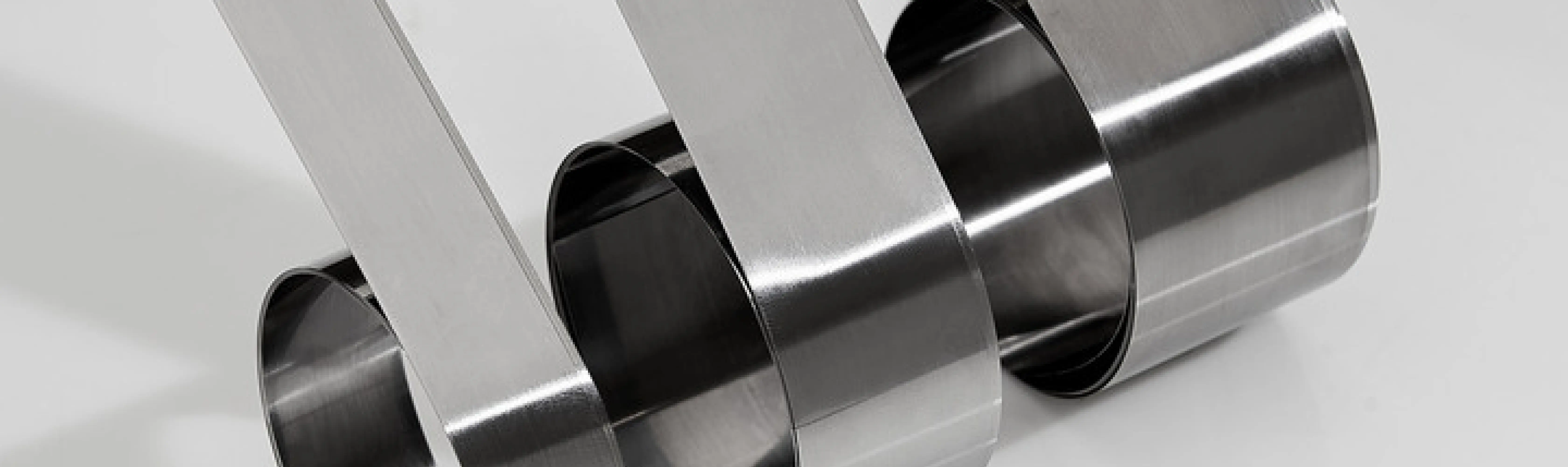

Doctor blades

Manufactured from a highly refined steel strip these superior quality lamella type doctor blades for the Rotogravure & Flexographic printing industry are produced by an ISO 9001: 2000 certified company. These doctor blades which are exported to many countries are available in several varieties and edge configurations based on customer specifications and process requirements.

Static Eliminators

The Sim Lanka team distinguishes itself by providing outstanding customer service and application expertise as we provide cost effective, practical solutions to your static control issues. Many Industries require specifically designed products for their application and as a result we offer a very comprehensive and customised product line for static neutralising as well as static charging devices and web/sheet cleaners.

Industrial oil purification

With the increase in concern and focus on energy conservation the world over, Sim Lanka too has made itself a part of this global initiative. Our solutions for oil cooling and cleaning enable machines to operate at peak efficiency without malfunction or breakdown.

Hydraulic Oil

If you were not aware that hydraulic oil could be used for more than 25 years, then you were also probably not aware that losses due to hydraulic system failure could be turned in to zero loss. That is the promise of ELC (Electrostatic Liquid Cleaner), LVDH (Low Vacuum Dehydration), and PHE (Plate Heat Exchangers).

While the ELC system is capable of removing contaminants irrespective of size, retarding oil oxidation and preventing sludge formation, the LDVH system, effectively removes water, air, and gases from oil at extremely low temperatures and thereby significantly reduces oxidation during the dehydration process. These oil coolers provide zero leakage, zero downtime, and zero defects which mean you could run machines in high heat, high humidity and dust, at peak levels of production with consistent quality.

If you have water in your oil, or your oil is black, or there is sludge in your sump, or you need to make frequent oil changes, or your system suffers from valve malfunction, or your filler in clogging regularly, or you have repeated machine breakdown or oil leakage, then you need to give us a call.

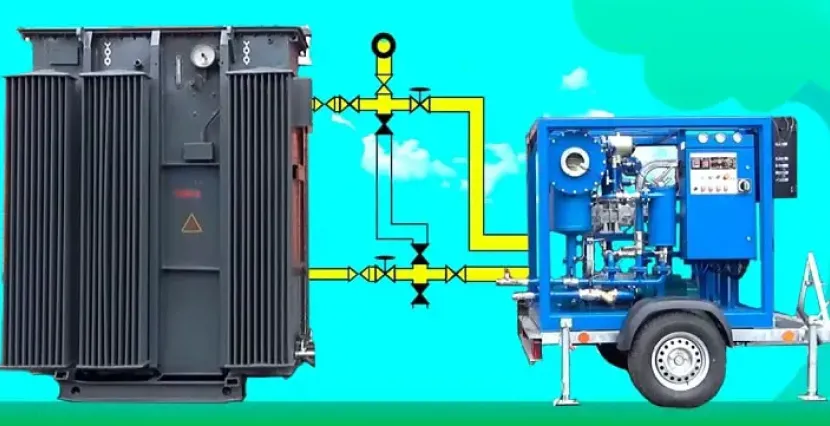

Transformer Oil

High-vacuum transformer oil filtration and dehydration plants are suitable for all types of electrical insulating oils. At Sim Lanka we have standard high-vacuum filtration and dehydration plants to remove moisture (free and dissolved), gases, dirt and oxidation products from mineral based and synthetic silicon oils and others. However, we could also provide custom built plants as per specific customer requirements.

The plants work on a low temperature, high vacuum principle and primarily consist of heating which aids the filtration and moisture removal process, filtration which removes suspended particles, and vacuum systems which remove moisture (emulsified and dissolved).

Other Industrial Oil

The Centrifugal Oil cleaner has been proved to be the most effective and efficient unit to address issues of high oil contamination as it removes particles suspended in oil, such as magnetic, non-magnetic, organic and inorganic matter and thereby doubles the life of oil. In addition, extended oil change periods, no replacement of elements, increased machine life and improved machine operation, reduced energy consumption and substantial savings on engine operation and maintenance expenses are some of the other vital benefits of continuously using a Centrifugal unit.